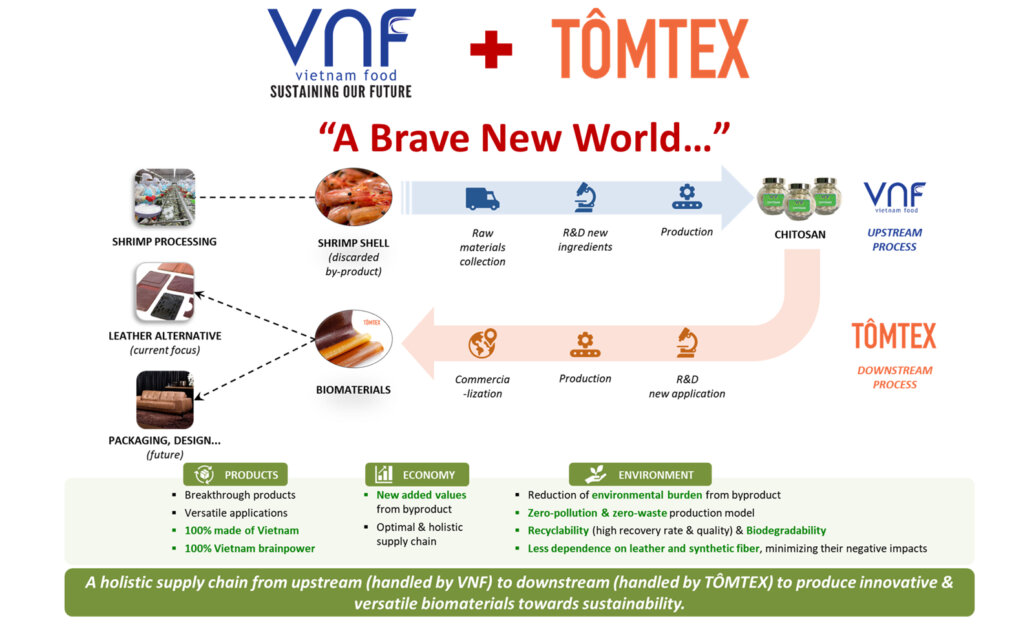

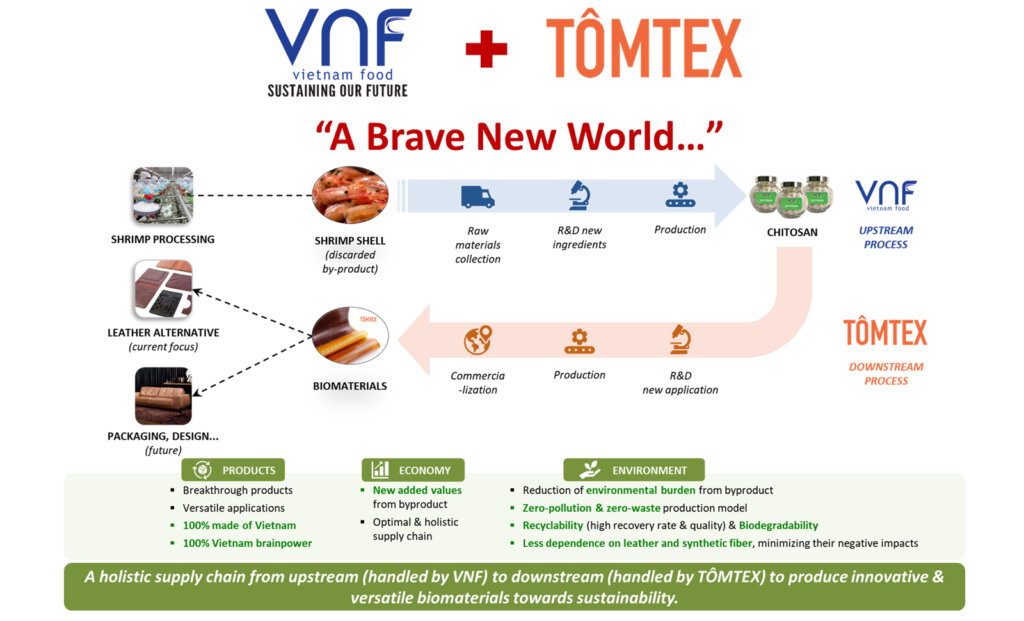

On November 15, 2021, Vietnam Food and TômTex signed an Memorandum of Understanding (MoU) to jointly develop Chitosan-based solutions for textiles and fashion applications, sustainably valorized from shrimp co-products.

Every year, the food industry generates up to 8 million MT of shrimp and crustacean shell waste. While we are used to thinking that only the animal’s meat is valuable, the by-product shell, in fact, contains a hidden treasure called: “Chitosan” – a natural polymer, tough and pliable (like a shrimp shell) with exceptional inherent functions, including biodegradability and antimicrobial.

This means every time we eat shrimp, we are generating waste and wasting value on many levels – in homes, restaurants, shops. In Vietnam, the seafood industry is a global leader, which means seafood waste overflows.

Modern problems require modern solutions. The answer to this problem here is: Innovation intertwined from Biotechnology and Biodesign.

VNF’s manufacturing abilities offers a uniquely sustainable supply of Chitosan – mass-produced via eco-friendly biotechnology. As a leading shrimp co-products processor in Vietnam, VNF has invested intensive R&D and technical advancement to manipulate the valorization of shrimp shells—the result being a versatile Chitosan portfolio. In today’s world, Chitosan is widely known but can be difficult to source transparently. Thus, VNF’s Chitosan offers accessibility and cost-competitiveness for a broad range of applications, quality specifications, purities, and forms – combined to provide a tailored Chitosan solution.

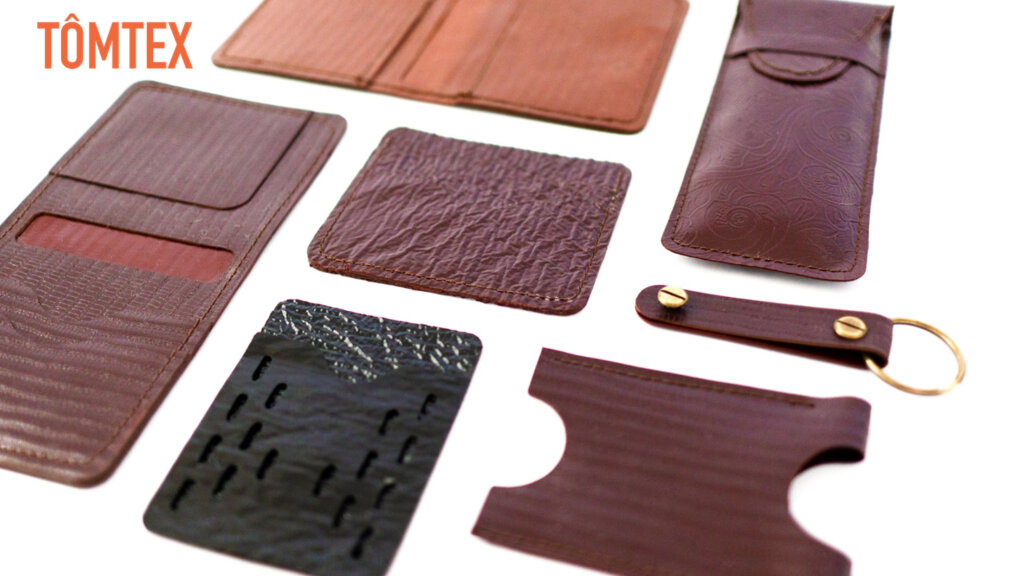

TômTex is a leading player in producing new-generation 100%-based material, created from two key ingredients: seashell waste and wasted coffee grounds. Tômtex’s flexible biomaterial offers brand designers creative freedom with fewer material constraints on size, thickness, and scaling – the aim to work as a sustainable and economical alternative solution. Most importantly, Tômtex’s biomaterial addresses the serious global problem with plastics. For example, vegan leather is often made from toxic polyurethane, and traditional animal-derived leather is hugely responsible for environmental pollution and greenhouse gas emissions.

Partnering together, VNF and TômTex will leverage each other’s strengths and pioneer a holistic value chain. Starting from VNF collecting and valorizing shrimp co-products into Chitosan, then integrated into TômTex’s biodegradable and plastic-free bioleather. Altogether, a start-to-finish process simultaneously solving the problem of waste and delivering innovative products into consumers’ hands.

“We are committed to combining our art, science, and technology expertise to create the most sustainable and high performing biomaterials to enable day-to-day consumer adoption. At TômTex, we believe that regular consumer adoption of environmentally friendly biomaterials is a critical step to slowing climate change and safeguarding the future. We focus on developing materials that make it easy for brands to reimagine their products and connect to their consumers. Sustainability alone won’t be the solution, environmentally-aware consumers will adopt only if aesthetics, performance, and accessibility criteria are met,” says Uyen Tran, designer and founder of TômTex.

With a founding team built of strong Vietnamese individuals, VNF and Tômtex’s cooperation will prove the strength of the Vietnamese supply chain and ability to innovate together from all corners of the world. A homage to TômTex’s lead designer’s roots, the name “Tôm” means shrimp in reference to discarded shells.

It is a harsh wake-up call, but the world is undoubtedly running out of raw materials. With the urgency of climate action and the fashion industry’s strides towards becoming more sustainable, Chitosan-derived biomaterials offer an unprecedented solution to multiple industries. We hope our work helps consumers consider the life cycle of natural resources, as we transform the infinite value of shrimp co-products (found right in Vietnam) into an empowering solution to preserve and advance the world’s future.